Let’s look at active solar heating systems that make use of solar gain, but harnesses it by active means such that the energy collection and storage potential is multiplied by using mechanisms such as pumps and fans. If you talk with a solar engineer, you’ll learn that passive solar systems are the most reliable, but you’ll also find that active solar systems can be well worth the additional cost of installation and operation.

As an introduction to active solar heating systems, let me remind you that plant roots respond well to warm soil. Many plant varieties don’t care as much about air temperature as they do about soil temperature. And, with any solar heating system, we’ll need a large amount of thermal mass to act as a type of “thermal battery.” What better thermal mass might one find in a greenhouse than the entire planting bed filled with moist soil? With our plants needing warm soil, and our solar system needing large amounts of thermal mass, the following active solar heating systems serve as examples of how we might satisfy both of those interests at the same time.

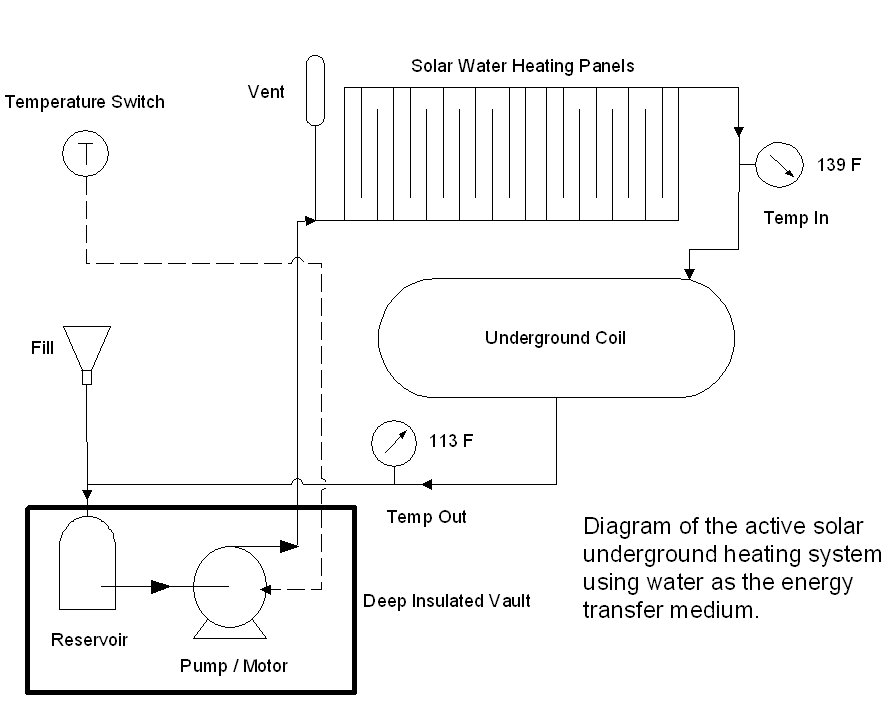

Underground Heating with Hot Water

A relatively simple and effective active solar heating system can be created by pumping hot water underground to heat the soil. Hot water for the system can be easily obtained by using solar panels designed to heat water. If the hot water tubing is placed deep enough in the ground, it won’t be affected by digging forks, shovels or roto-tillers. If closed cell foam insulation is used underground around the perimeter of the greenhouse, which will minimize conduction from warm greenhouse soil to outside soil that might be exposed to below freezing temperatures. If an underground storage tank is used, then the system can be a drain-back design which obviates using anti-freeze in the system.

System Installation

Before construction of the greenhouse, excavation would be undertaken to remove about 18 to 24 inches of soil. At that level, flexible water piping, capable of handling hot water, perhaps an inch in diameter, could be installed in single large coiled pattern, with each pass of the coil being spaced about six inches apart.

The large pipe coil would be attached at one end to an underground tank and pump combination where the pump would take suction off of the tank, and both the tank and pump would be slightly lower than the coil to promote water draining back into the tank. The other end of the coil would be attached to the outflow of several solar water heating panels that would be fed by the pump and tank combination. A stand pipe would be installed to vent the system to allow steam and pressure to escape.

Ideally, the tank and pump would be installed in an insulated access vault, and the tank would have a level indicator to allow level to be checked periodically. It would also have a filling port for makeup water that will be required due to system evaporation from the vent. The pump would be operated by a temperature switch incorporated into a small simulated solar panel such that the switch would be activated based on sunlight sufficient to heat up the solar water heating panels.

Insulation around the perimeter of the greenhouse would be installed below grade level to help prevent warmth associated with greenhouse soil from being extracted through conduction from the surrounding cooler soil. The insulation would be rigid closed-cell foam that would resist absorbing moisture and be self-supporting and resistant to crushing when backfill material is placed against it.

System Operation

When sunlight brings the solar panels up to a reasonable operating temperature, the temperature switch would turn on the pump. Working under suction head provided by natural hydrostatic pressure, the pump would draw water from the underground tank and pump it through the hot solar water heaters and down into the underground coil so it could return to the tank to be recycled. The piping would give up heat readily to the soil and return cooler water to the tank to be reheated by the solar water heaters.

When the sunlight proves insufficient to activate the temperature switch, the system would shut off and drain back into the underground coil and reservoir. Drain back would occur from both sides of the pump such that all water in the system would be safely underground in the coil or reservoir, protected from freezing temperatures that might be reached both inside and outside the greenhouse.

Steam created from water entering the hot solar panels would be vented by the stand pipe, and the system would be refilled as needed over the course of operation.

Underground Heating with Air

This system is also relatively simple, yet it operates using a very different heat transfer mechanism – air. As such, blowers are necessary to make the system work. The system uses heated air from the very top of the greenhouse to warm the soil beneath the growing area. Unlike the solar water heating system, this design could be set to run nearly continuously, either charging up the soil beneath the growing area during the day or extracting warmth from the soil to heat the greenhouse air at night.

Installation

Before greenhouse construction, excavation would remove about 18 to 24 inches of soil where moderate diameter piping, perhaps six inches in diameter, would be installed as a type of heat exchanger buried in the soil. Schedule 20 PVC or similar black ABS piping would be candidates to consider. Each tube would be sturdy and corrosion resistant, but thin enough to permit easy transfer of energy to and from the soil. Tubes would be spaced about six inches apart. Once soil was replaced, the tubes would enjoy enhancement of strength from the surrounding soil, such that concern of collapsing under the weight of soil and personnel would be eliminated.

The tubes would be connected to a header at one end of the greenhouse that leads to a central blower mounted at the ridge of the structure. This would form the intake for the tubes. The exhaust end of the underground tubes would each have a damper and a diffuser mounted close to ground level. These would be installed at the end of the greenhouse farthest away from the intake blower.

The blower would be operated by two temperature switches inside the greenhouse, mounted at the midway point on the ridgeline. One switch would be set to activate at a temperature below that set for the normal exhaust vents and fans. The other switch would be set to activate at a much lower temperature, perhaps near the point at which plants inside would be stressed by cooler temperatures.

Insulation around the perimeter of the greenhouse, well below grade level, would be installed to help prevent soil warmth from escaping, through conduction, out into cooler soil surrounding the structure. The insulation would be rigid closed-cell foam that resists absorbing moisture.

Operation

During the daytime when the sun is shining, the blower would activate based on the high set point temperature switch and take excess heat from the ridgeline and blow it through the header and into the tubing buried beneath the soil. The tubing would heat up and give off heat to the surrounding soil, thus charging up the soil like a large thermal battery. When greenhouse temperatures cool down, because of the effect of the blower or because of diminished insolation, the blower would shut down.

As greenhouse temperatures continue to fall at night, the low set point temperature switch would activate, starting up the blower, and it would rob thermal energy from deep in the soil to maintain minimally acceptable air temperatures inside the structure.

Diffusers at the exhaust end would eliminate strong air flows that might bother plants. Dampers at the exhaust end would be used to balance the flow coming from each diffuser such that each tube underground would receive roughly the same amount of warm air flow.

Pros and Cons

Both systems have their good points and bad points. Let’s take a glance at each.

The water-based system will be effective at collecting and distributing thermal energy because water is a good conductor of heat and an excellent thermal storage medium. It also lends itself to better heat transfer because of the large amount of surface area relative to a small diameter water pipe. The drawbacks are the danger of freezing, corrosion of the pump and reservoir, the need for venting and makeup water, and the possibility of leaks.

The air-based system is simple to operate because it doesn’t introduce any other heat transfer medium – it simply uses greenhouse air. It also serves as a means of directly and actively heating greenhouse air instead of allowing the soil to slowly release energy back through natural convection. Lastly, it creates air flow in the greenhouse which is normally very good for plants. The drawbacks of the system are the limited ability of air to transfer heat to the soil, despite good surface area contact by the large diameter tubing, and blower noise during system operation.

The next two articles of this series will take a closer look at thermal mass and insulation, two important elements of any solar heating system, whether it be passive or active.

Clair Schwan builds his own greenhouses and creates them with both passive and active solar collection systems. His primary interest is solar collection from late fall to early spring since he enjoys stretching his growing season and taking cold-hardy cultivars into the single digits during the winter months.

Related Articles & Free Email Newsletter

Making Your Own Cloche from Just About Anything

Passive Solar Heating for Greenhouse Operations

Comment here